acrylic, polyurethane sealant, epoxy sealants, Stone adhesives, abrasives, waxes, Sealers and impregnators

acrylic, polyurethane sealant, epoxy sealants, Stone adhesives, abrasives, waxes, Sealers and impregnators

EPOXY ADHESIVE, STRUCTURAL, BI-COMPONENT, FAST POLYMERISATION, FOR BUILDING MATERIALS, BRICKS, CERAMIC PRODUCTS, MARBLE, GRANITE, WOOD, METAL

The product is expressily formulated for mechanical application on ceramic materials and is based on epoxy resin reinforced by mineral fillers and catalized by a mix of aminic hardeners in order to obtain a quick hardening also at room temperature. The different color of the two components allows a sight control of the homogeneity of mixing. Furthermore, once hardened and completed the catalysis (24-48 hours after the application), the product can get in contact with the water of swimming pools and thermal waters.

COMPOSITION

COMPONENT A: epoxy resins bisphenol A/F, mineral fillers and mineral pigments.

COMPONENT B: mix of agents of catalysis containing amine adducts, mineral fillers and mineral pigments MIXING RATIO The epoxy adhesive need exact mixing ratio in weight between the component A (resin) and the component B (catalyst), and in this case: COMPONENT A : COMPONENT B = 100 : 100 (i.e.: 1 kg of component A mixed with 1 kg of component B) PHYSICAL CHARACTERISTICS COMPONENT A COMPONENT B

MIXTURE

Color light grey dark beige cement grey Specific weight (g/cm3 ) 1,50 ± 0,20 1,50 ± 0,20 1,50 ± 0,20 Using time after mixing (100g. comp. A + 100g. comp. B) at 25°C/77°F 10-20 minutes Hardening time after mixing (100g. comp. A + 100g. comp. B) at 25°C/77°F 55-65 minues Total hardening time (complete cross-linking =100%) 4-5 days

IMPORTANT: the product doesn’t harden at temperature lower than +10°C/50°F Temperatures higher than +30°C/86°F reduce excessively the using/hardening time

PREPARING THE SURFACE

The pieces to be worked/bonded must be porous, dry, free from dust, greasy and alien substances and, if needed, mechanically roughened.

APPLICATION

Mix carefully the two components with the above mentioned mixing ratio until the complete homogeneity of the mixture without lumps, till to homogeneous colour, and apply the adhesive IMPORTANT For materials of low or you very low porosity (i.e.: glass), in order to have to have a mechanical seal with a good degree of safety, you must make a joint or insert fixing pins.

THICKNESS

The best adhesive characteristics are obtained with thicknesses of adhesive from 0.3 to 1.0 mm.

STABILITY

The product is stable 12 months in the original and closed cans stored at temperatures between +10°C/50°F and +30°C/86°F Protect from frost the stored cans.

POLYMERISATION

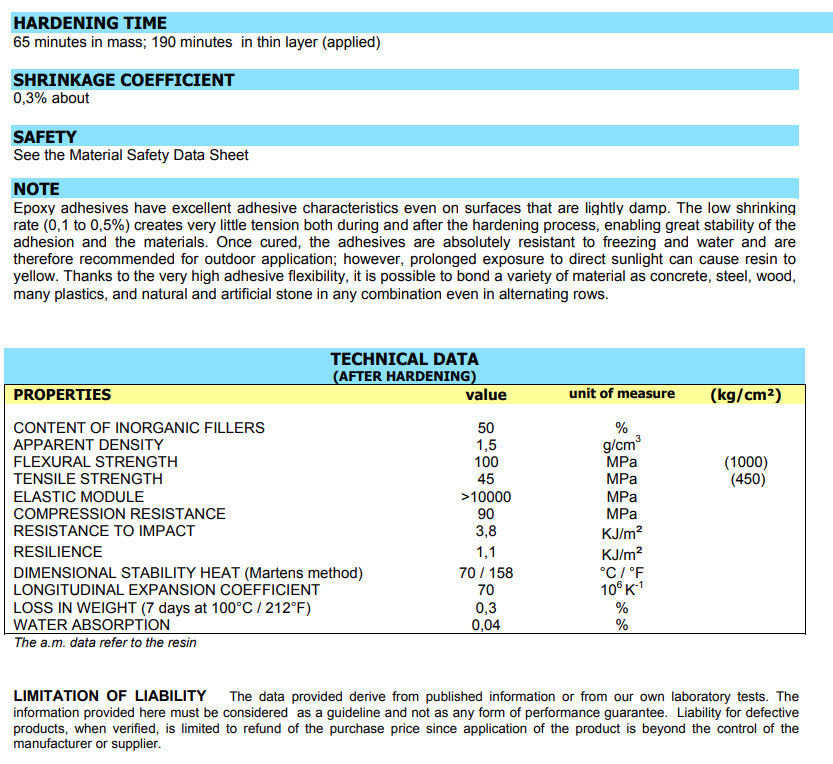

The polymerization rate increases with increasing temperature. The application temperature must not be lower than +10°C / 50°F Suggested application temperature between +10°C/50°F and +30°C/86°F