5-axis Machining center and Bridge saw

Stone Factory MachinesStone Finishing, Profiling MachinesCNC Working Center

HELIOS

Italy

Italy

Usage: Granite, Marble, Limestone, Onyx, Quartzite, Sandstone, Travertine

Machinery Function Features

Helios Five is an extremely precise 5-axis machining center and bridge saw (6 axis with the lathe), with automatic tool change and magazine, that can be extended according to specific needs. The possible configurations make the machine suitable for the execution of important works, from roughing to finishing, with highly detailed results. The precision of the Helios Five allows to achieve the greatest part of the stone processes possible, such as small and large sculptures and statues, kitchen tops with profiling and edge polishing, drain boards and much more. This feature makes Helios Five unique in its category.

As a bridge saw, the machine can work with disks with diameters of up to 725 mm. Thanks to its imposing structure and the technology developed by Helios. Helios Five can process all types of cut with extreme precision (45° angled cuts, shaped cuts, arches cuts angled on both sides etc…)

Helios Five can have the Z stroke of 680, 1000 or 1200 mm and can be equipped with the interpolated lathe, thus increasing the executable machining in the stone sector.

Stainless steel structure: Thanks to the stainless steel structure, Helios Five is a sturdy machine, that preserves its quality over the time;

Precision and reliability: The use of recirculating ball screws and zero backlash gears makes the machine’s movements extremely precise, thus producing highly detailed works;

High frequency inverter: Thanks to the use of high frequency inverter, that provides only the necessary power for the mechanical efficiency, there are no wastes of energy, and the maximum energy saving is guaranteed;

Security doors: The security doors have got a manual sliding system with automatic machine stopping sensor in case of opening;

Laser marker: The device shows in advance the passage of the disk, indicating the correct position of the cut;

Aluminium rectified table: The aluminium rectified table guarantees the integrity of the table and a total resistance to the processes stress and to corrosion. The

calibration, performed directly by the machining center, ensures the perfect flatness of the support surface. The rectified table and the separated slats offer the

possibility to set the pieces easily;

Tilting table: The tilting table, with the Easy-load solution, ensures the loading of any type of slab with the minimal effort;

Automatic tool change and tools magazine: Helios Five with automatic tool change manages all the machining center functions. The magazine, containing several tools ensures the maximum versatility in the tools choice. Its capacity can be modified according to specific needs.

Software

Run-touch - Galaxy Stone software: Helios Five is managed by the Run-touch and Galaxy Stone software, that allow to use the machine like a bridge saw or a machining center;

Photoscan system: The Photoscan system, with the integrated Run-touch software, is the exclusive device that makes the cutting process very easy. The Photoscan is the scanning system of the slabs, as well as measurement device and template reader. Combined to the Helios bridge saws, It takes one picture of the slab and the cutting process can start easily without any further measurement. Among the other features, Helios PhotoScan can detect the position of a template on the slab and in a few simple steps, the cutting process can start;

Command consolle: The command consolle includes everything you need to control the machine: the touch screen display, the mouse, the keyboard, the command buttons, and the joystick. It is possible to use the machine remotely thanks to the portable consolle.

Technical Data

| Parameters |

Unit |

Five |

Five 1000 |

Five 1200 |

| Standard voltage |

Volt |

400 V (3P + N + GND) 50/60 Hz |

400 V (3P + N + GND) 50/60 Hz |

400 V (3P + N + GND) 50/60 Hz |

| Y axis rapid speed |

m/min |

35 |

35 |

35 |

| Tool-holder spindle motor power |

kW |

15 |

15 |

15 |

| Total Power required |

kW |

25 |

25 |

25 |

| Disk hole diameter |

mm |

95 |

95 |

95 |

| Min. diameter of the blade |

mm |

400 |

400 |

400 |

| Tool holder cone |

|

ISO BT 40 |

ISO BT 40 |

ISO BT 40 |

| Z axis stroke |

mm |

680 |

1000 |

1200 |

| Max. diameter of the blade |

mm |

7250 |

7250 |

7250 |

| W axis rotation |

° |

0° - 360° |

0° - 360° |

0° - 360° |

| Y axis stroke |

mm |

2250/3900 |

2250/3900 |

2250/3900 |

| A axis rotating (degrees) |

° |

0° - 90° |

0° - 90° |

0° - 90° |

| Dimensions of the work table (length x width) |

mm |

3000 x 2000 |

3000 x 2000 |

3000 x 2000 |

| X axis stroke |

mm |

3700 |

3700 |

3700 |

| Z axis rapid speed |

m/min |

10 |

10 |

10 |

| Max cutting depth |

mm |

230 (725 in disk) |

230 (725 in disk) |

230 (725 in disk) |

| Machine overall width |

mm |

4700/6300 |

4700/6300 |

4700/6300 |

| Machine overall height |

mm |

3955 |

4697 |

4900 |

| Machine overall length |

mm |

6700 |

6700 |

6700 |

| X axis rapid speed |

m/min |

35 |

35 |

35 |

| Tool-holder spindle rotation speed |

rpm |

0 - 7000 |

0 - 7000 |

0 - 7000 |

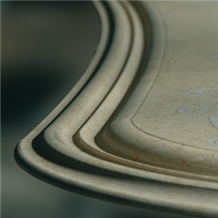

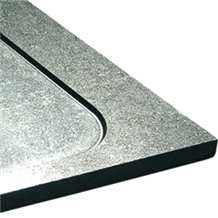

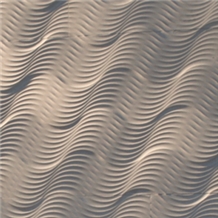

Processed Stone Photos

-

Fireplaces

-

Capitals

-

Lettering

-

Columns

-

Frames

-

Engravings

-

Drain boards

-

Decorative pieces

Supplier Detail

Helios Automazioni Srl

Established: Jan 01,2000

Italy

Main Product:

helios five, helios dea, helios cut 500, helios lux , helios evolution, helios edge lux

Ms.Daniele Cordesco

Tel:

0039-0873 341584

Adr:

Viale Francia, Zona Industriale - San Salvo (CH) Italy

Visit Store

Italy

Italy