stone splitting machine, stone cutting machines, stone splitter, pushing air bag, button bit grinder, dth hammer button bit

$3-3

7YR

7YR

stone splitting machine, stone cutting machines, stone splitter, pushing air bag, button bit grinder, dth hammer button bit

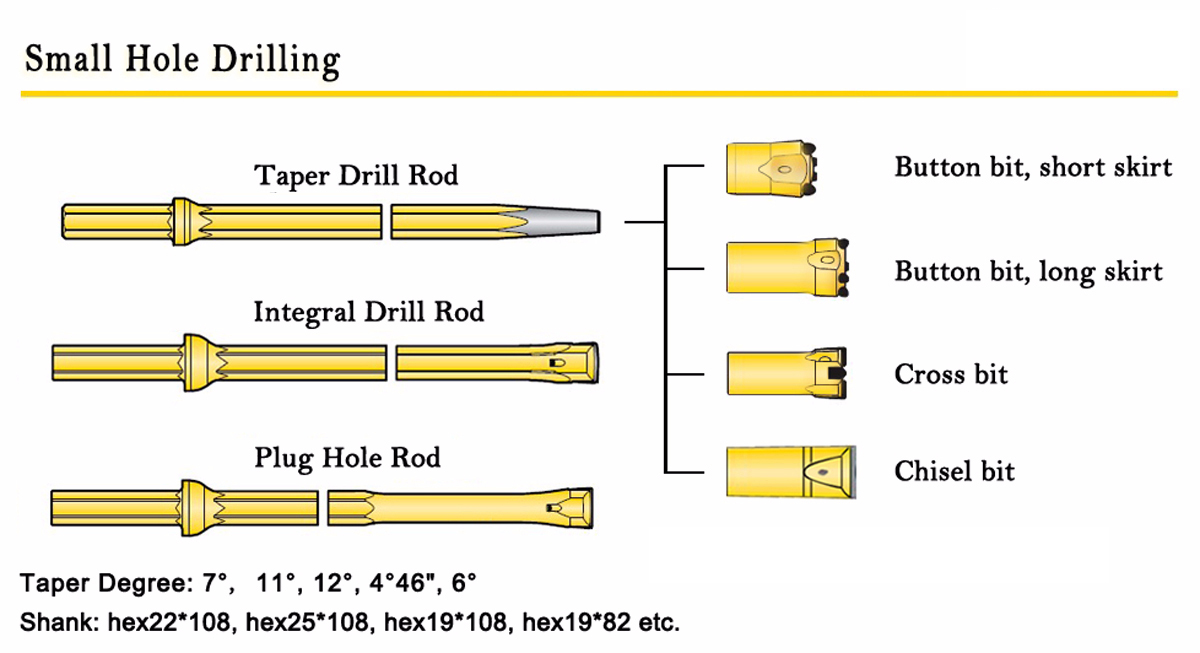

A complete assortment of integral drill steels, tapered rods and bits are available for hand held drilling, featuring unique cemented carbide with superior wear resistance and service life.

—Advantages:

Carburized rods give you best in class service life with increased productivity.

Tapered button bits offer extra wear resistance which means lower costs.

Wide assortment & OEM makes it easy to match the need.

Product quality ensures full control over the production tasks.

1. Tapered chisel bits

The tapered chisel bit is widely used in drilling holes with depth less than

5 meters and diameter ranged in 20-45 mm by light-duty rock drill, like Y6.

| Description |

Diameter |

Length |

Water hole |

|

Taper degree a=4° 6° 7° 11° 12° |

mm |

mm |

2 |

|

20 |

65 |

2 |

|

|

23 |

65 |

2 |

|

|

25 |

69 |

2 |

|

|

28 |

60 |

2 |

|

|

30 |

55 88 |

2 |

|

|

32 |

55 64 71 80 |

2 |

|

|

34 |

71 80 |

2 |

|

|

36 |

74 |

2 |

|

|

38 |

74 |

2 |

|

|

40 |

74 |

2 |

|

|

42 |

74 |

2 |

|

|

45 |

74 |

2 |

2. Tapered cross bits

The taper cross bits can be used under any rock drilling condition because of it's comprehensive adaptability. Compared with taper chisel bits, taper cross bits have a better drilling performance because carbide tips on cross bits doubled, which means carbides shape are cross type on drill bits. Taper cross bit is mainly used for hard or very hard rock formation.

| Description |

Diameter |

Length |

Weight |

|

Taper degree a= 6° 7° 11° 12° Socket inside diameter d=19, 22, 25 |

mm |

mm |

kg |

|

28 |

71 80 |

0.19 |

|

|

29 |

71 80 |

0.2 |

|

|

30 |

50 67 71 80 |

0.3 |

|

|

32 |

50 67 71 80 |

0.3 |

|

|

33 |

71 80 |

0.32 |

|

|

34 |

67 71 80 |

0.34 |

|

|

35 |

67 71 80 |

0.35 |

|

|

36 |

71 80 |

0.36 |

|

|

38 |

67 71 80 |

0.42 |

|

|

40 |

71 80 |

0.43 |

|

|

41 |

71 |

0.45 |

|

|

42 |

69 80 |

0.46 |

|

|

44 |

80 |

0.47 |

|

|

45 |

80 |

0.5 |

3. Tapered button bits

Comparing with tapered chisel bits and tapered cross bits, button bits has higher technology, much longer primary drilling time and higher drilling efficiency, so that the button bit is popular among the users.

According to the tungsten carbide insert, tapered button bits can be divided into the types of hemispherical button, conical button and parabolic button, etc.

Button bits with hemispherical button is for high bearing capacity and abrasive resistance while conical button and parabolic button are for high drilling speed and low abrasive resistance.

| Description |

Diameter |

Length |

No. of |

|

Taper degree a= 4o46" 6o 7o |

mm |

mm |

pcs |

|

28 |

50 |

4 |

|

|

29 |

50 |

4 5 6 7 |

|

|

30 |

50 80 |

5 6 7 8 |

|

|

32 |

50 55 71 80 |

6 7 8 9 |

|

|

33 |

50 55 71 80 |

6 7 9 |

|

|

34 |

50 55 |

7 8 |

|

|

35 |

55 71 80 |

4 5 6 7 |

|

|

36 |

50 55 |

7 |

|

|

37 |

55 |

4 6 7 |

|

|

38 |

50 55 |

4 6 7 |

|

|

40 |

7 |

||

|

41 |

50 55 71 |

4 5 |

|

|

42 |

50 |

6 7 |

|

|

45 |

50 55 71 |

6 7 8 9 |

Suitable Machine: hydraulic rock drill, pneumatic jack hammer, gasoline rock drill

Suitable Block: granite and marble

Each of rock drill bit is produced in different sizes and designs in order to optimize their application to a broader scope of rock drilling conditions and correspond to different job requirements.

To ensure the normal service life, taper drill bits need to be matched well with taper drill rods, the taper degree must be the same between taper drill bits and taper dill rods.