white fused alumina, brown fused alumina, silicon carbide, chromite sand, garnet, boron carbide

$1100-1200

white fused alumina, brown fused alumina, silicon carbide, chromite sand, garnet, boron carbide

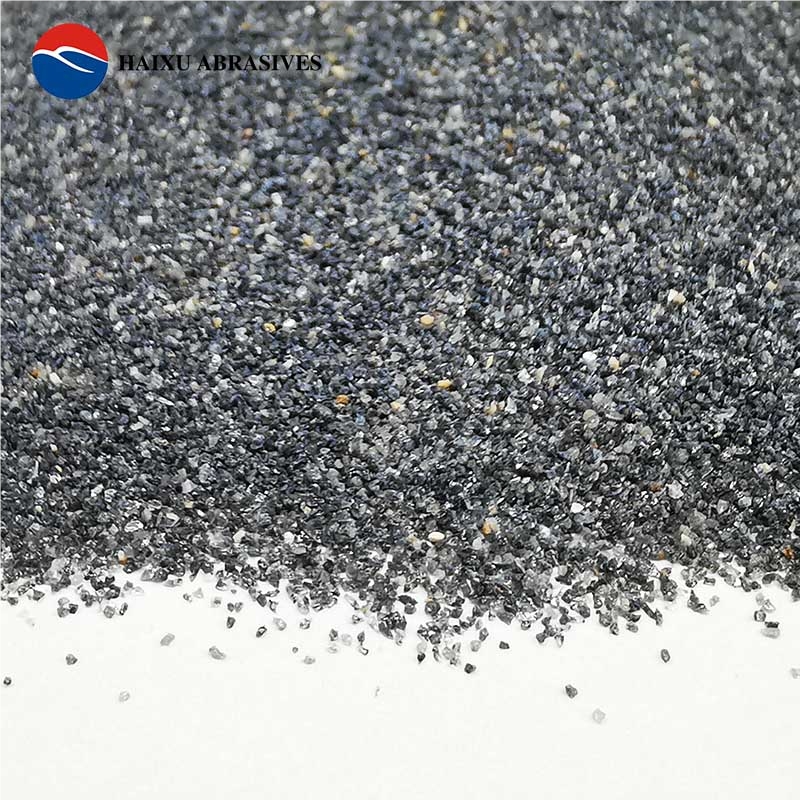

Blue fired aluminum oxide abrasive grain for cutting wheels

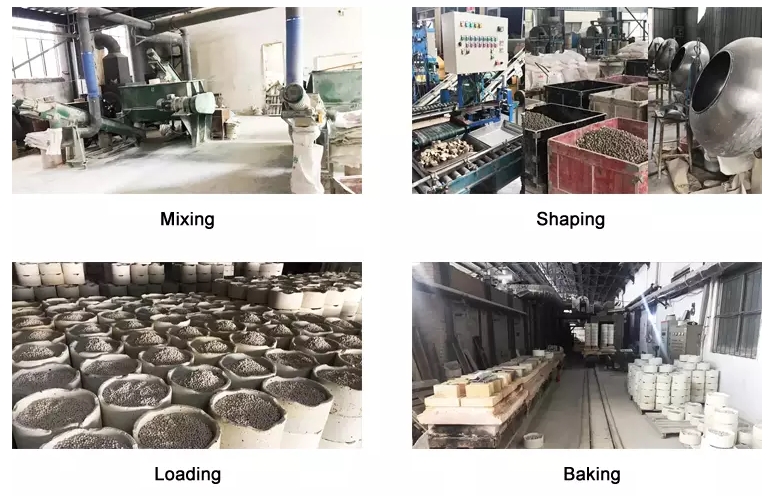

Blue fired brown aluminum oxide is calcined at a temperature of about 1350℃ after the normal production process of brown fused aluminum oxide. It is also called high-temperature calcined brown fused alumina(Compared with medium-temperature calcined brown fused alumina at 1050℃). The impurities existing in the grains will be separated out & vaporized. The calcining treatment eliminates the cracks of brown fused alumina grain outside and inside. The surface of each particle changes coarser, improving the hydrophilicity and self-sharpening greatly. So the abrasive grains will easily get bonded with the resin bonder. Thus it can improve cutting wheel performance which adopts this abrasive material.

Blue fired aluminum oxide abrasive grain for cutting wheels Features:

Blue fired aluminum oxide abrasive grain for cutting wheels Physical and Chemical Composition

|

Physical Properties |

|

|

Knoop Hardness |

1990-2290 |

|

Hardness: Mohs |

Min 9.0 |

|

Specific Gravity |

Min 3.95g/cm3 |

|

Bulk Density |

1.55-2.05g/cm3 |

|

Melting Point |

2250℃ |

|

Hydrophilicity |

186mm (F46) |

|

Toughness |

66% (F24) |

|

Particle Shape |

Blocky, Sharp |

|

Color |

Blue |

|

Chemical compositions[%] |

|

|

Al2O3 |

94.5-96 |

|

SiO2 |

0.8-1.2 |

|

Fe2O3 |

0.05-0.2 |

|

TiO2 |

2.5-3.5 |

|

CaO |

0.2-0.25% |

Applications

Bonded abrasive tool (F-grit)

Coated abrasive tool (P-grit)

Vitrified abrasive tool

Reusable abrasive

Grinding,lapping & polishing medium

Heavy load grinding wheels

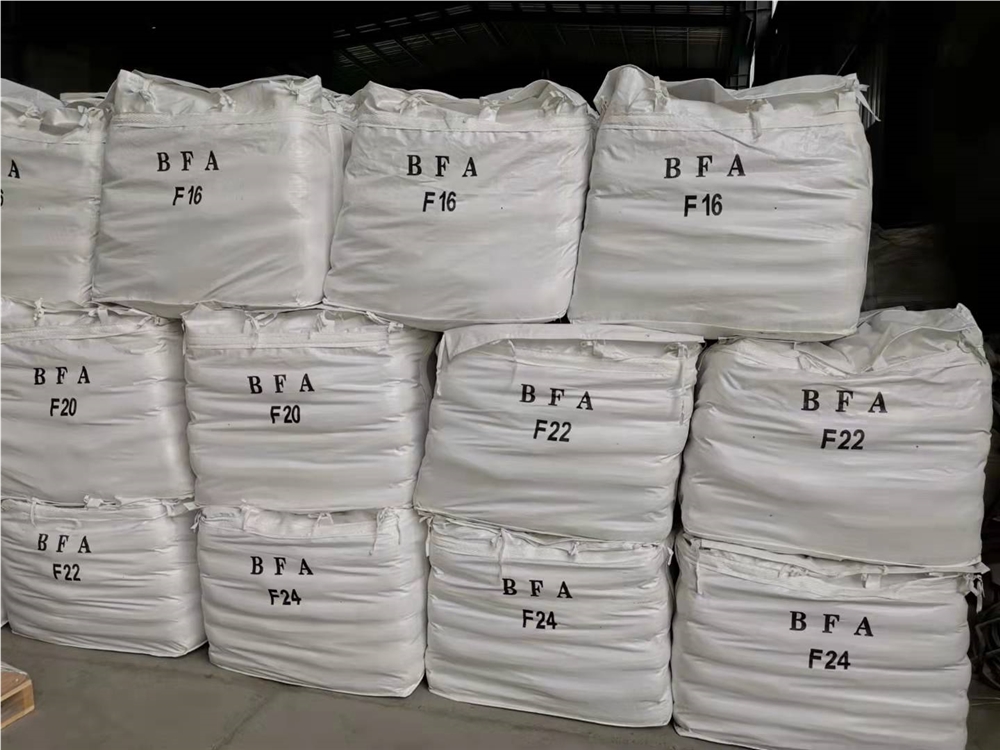

Typical Size for F-grit (Barnac milling) and P-grit(Barnac)

|

Grit designation |

Mean diameter in um |

Bulk Density(LPD) in g/cm3 |

|

F12 |

1765 |

1.95-2.05 |

|

F14 |

1470 |

1.94-2.04 |

|

F16 |

1230 |

1.92-2.02 |

|

F20 |

1040 |

1.91-2.01 |

|

F22 |

885 |

1.90-2.00 |

|

F24 |

745 |

1.89-1.99 |

|

F30 |

625 |

1.87-1.97 |

|

F36 |

525 |

1.83-1.93 |

|

F40 |

438 |

1.81-1.91 |

|

F46 |

370 |

1.79-1.89 |

|

F54 |

310 |

1.76-1.86 |

|

F60 |

260 |

1.74-1.84 |

|

F70 |

218 |

1.72-1.82 |

|

F80 |

185 |

1.70-1.80 |

|

F90 |

154 |

1.67-1.77 |

|

F100 |

129 |

1.65-1.75 |

|

F120 |

109 |

1.63-1.73 |

|

F150 |

82 |

1.60-1.70 |

|

F180 |

69 |

1.57-1.67 |

|

F220 |

58 |

1.55-1.65 |

|

P12 |

1815 |

1.95-2.05 |

|

P16 |

1324 |

1.93-2.03 |

|

P20 |

1000 |

1.91-2.01 |

|

P24 |

764 |

1.89-1.99 |

|

P30 |

642 |

1.86-1.96 |

|

P36 |

538 |

1.84-1.94 |

|

P40 |

425 |

1.81-1.91 |

|

P50 |

336 |

1.78-1.88 |

|

P60 |

269 |

1.75-1.85 |

|

P80 |

201 |

1.73-1.83 |

|

P100 |

162 |

1.69-1.79 |

|

P120 |

125 |

1.66-1.76 |

|

P150 |

100 |

1.63-1.73 |

|

P180 |

82 |

1.60-1.70 |

|

P220 |

68 |

1.57-1.67 |