stone splitting machine, stone cutting machines, stone splitter, pushing air bag, button bit grinder, dth hammer button bit

$150-300

7YR

7YR

stone splitting machine, stone cutting machines, stone splitter, pushing air bag, button bit grinder, dth hammer button bit

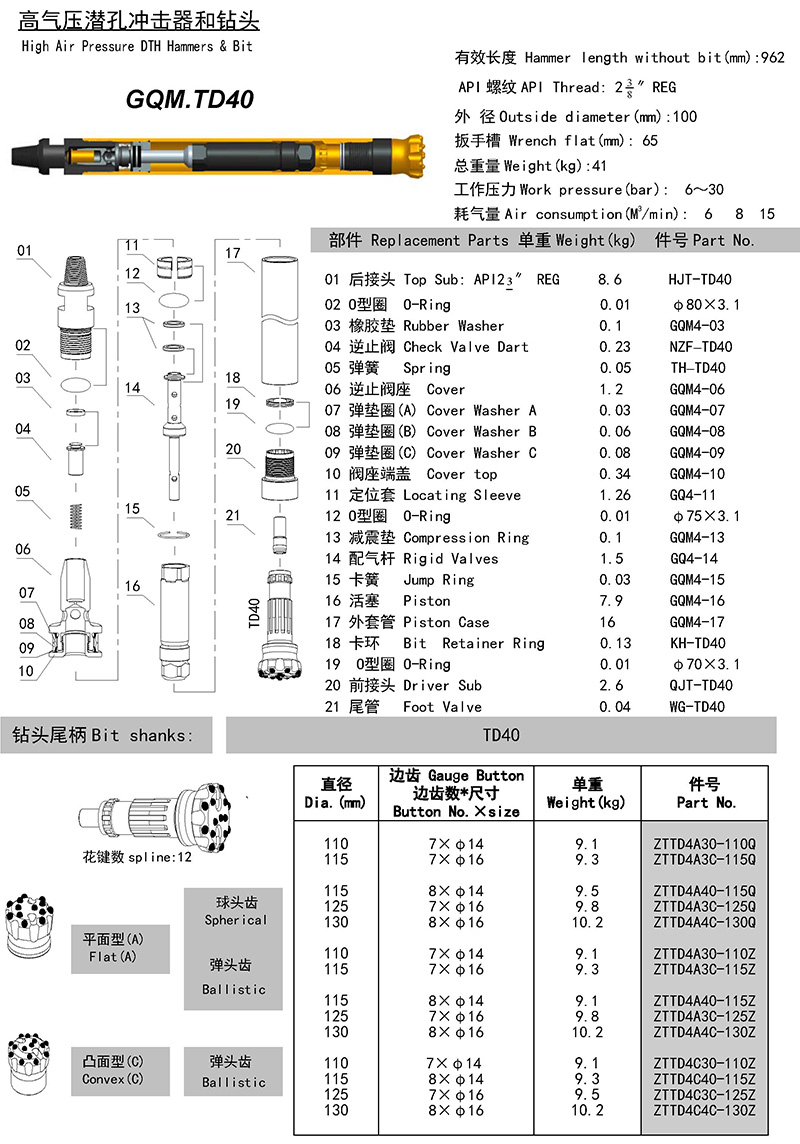

Description for DTH TD40 drill button bit set :

1.Mterial: DTH TD40 drill bit set made from 45CrNiMoV alloy steel , Carbide :Element T6 .

2.Type: Hot-press inserting .

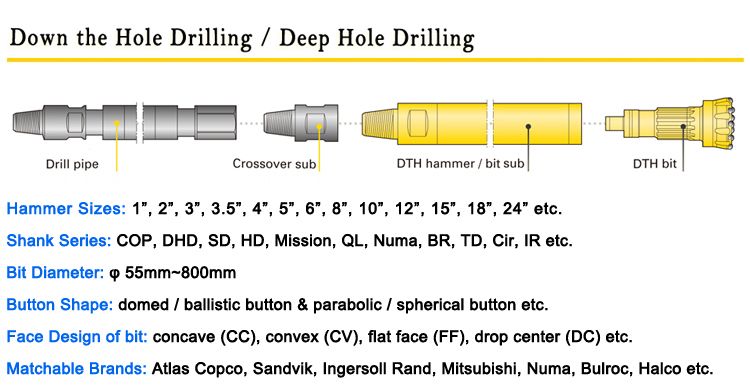

The DTH bits is the tool cutting rock. Bestlink DTH bits are made of superior quality alloy steel which is made by Timken in U.S. Besides, all our DTH bits are using the brand "Element Six" T.C carbide which provides (the T.C buttons) for Boart Longyear. In addition art manufacturing technology makes our DTH bits with higher and more reliable quality.

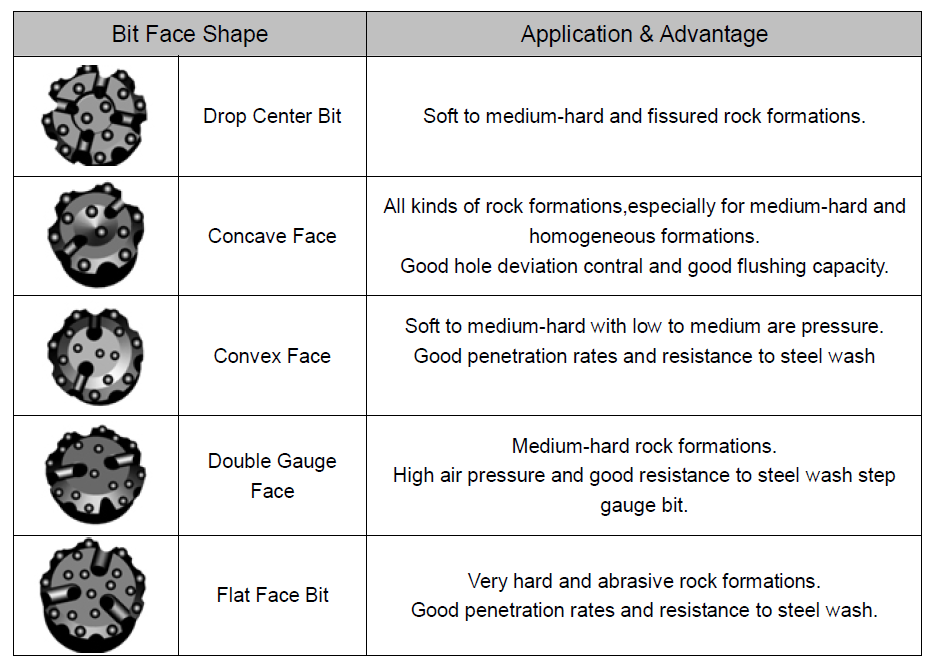

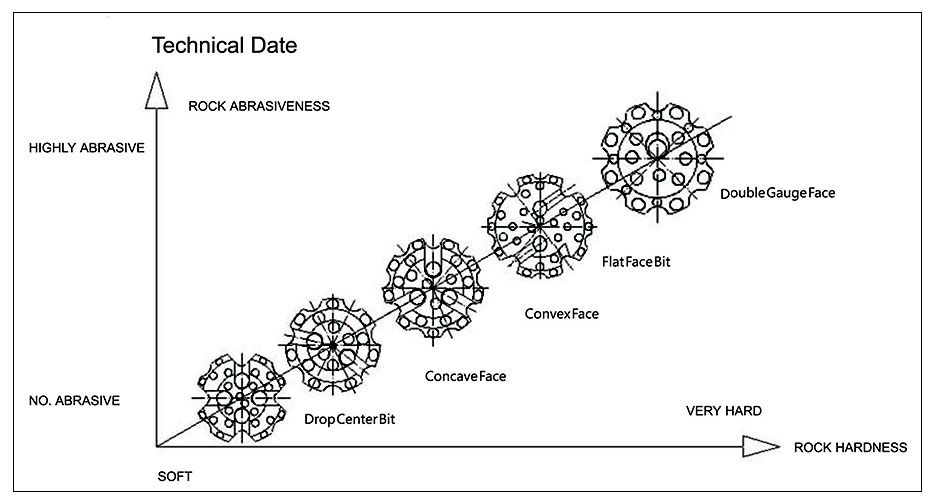

Different face style makes DTH bits suitable for various rock conditions.

Flat face: This is an universal design, especially for hard and abrasive rock formation. So typically, flat face with hemi-spherical buttons design is the most popular choice.

Convex face: A classic design for soft to medium hard rock formation which is not so abrasive. This design have very excellent penetration rate but poor in hole deviation if rocks are hard.

Concave face: Medium hard to hard rock formations which is less abrasive and fractured. Especially for deep hole drilling, excellent control over hole deviation.

DGR face: A special design for hard or very hard rock conditions, double gauge row buttons provide very excellent ware-resistance and very longer life time. It is usually used for some bigger diameter DTH bits.

Besides, we are manufacturing the DTH bits with various shanks so they can be compatible with different DTH hammers.