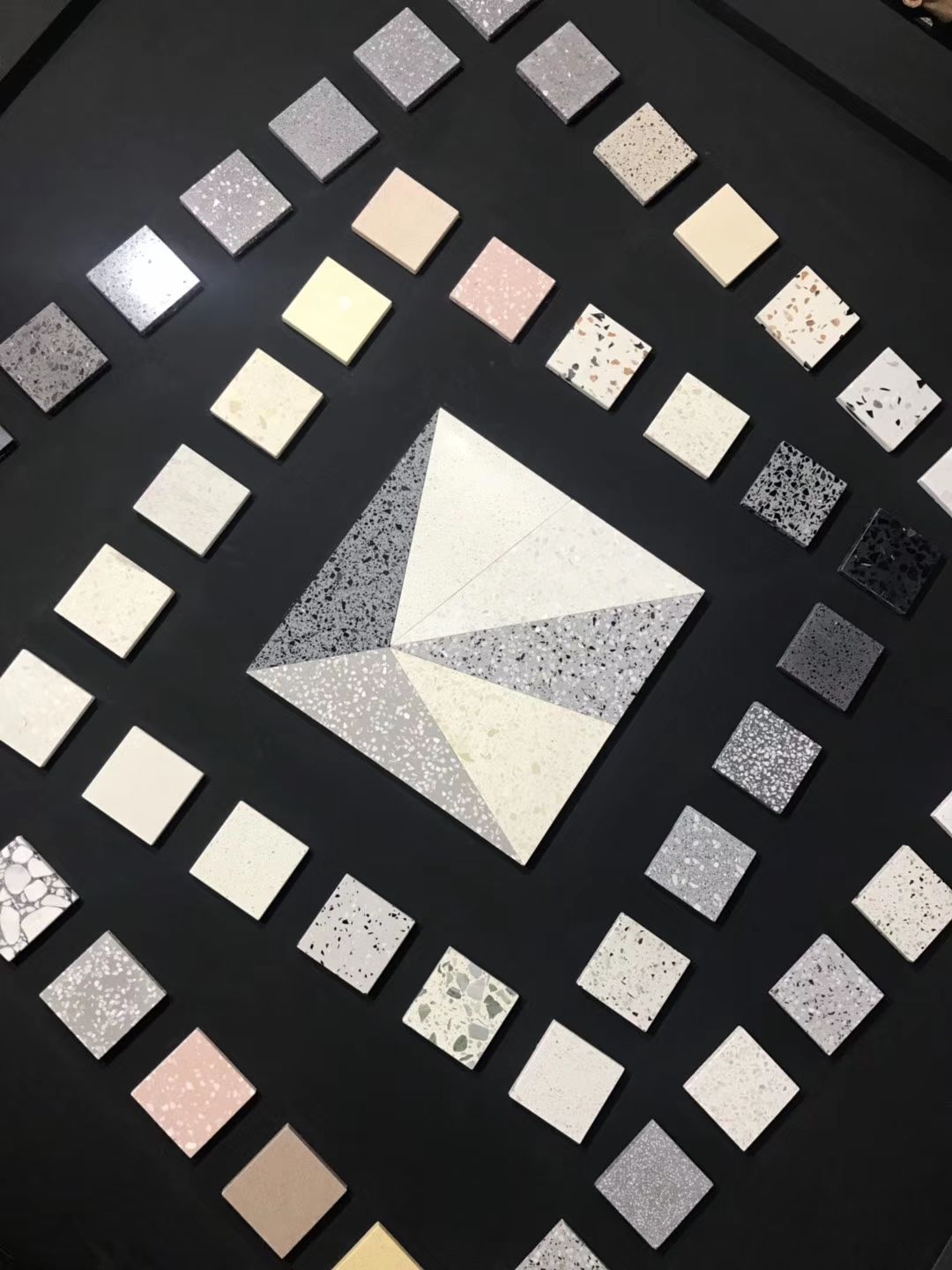

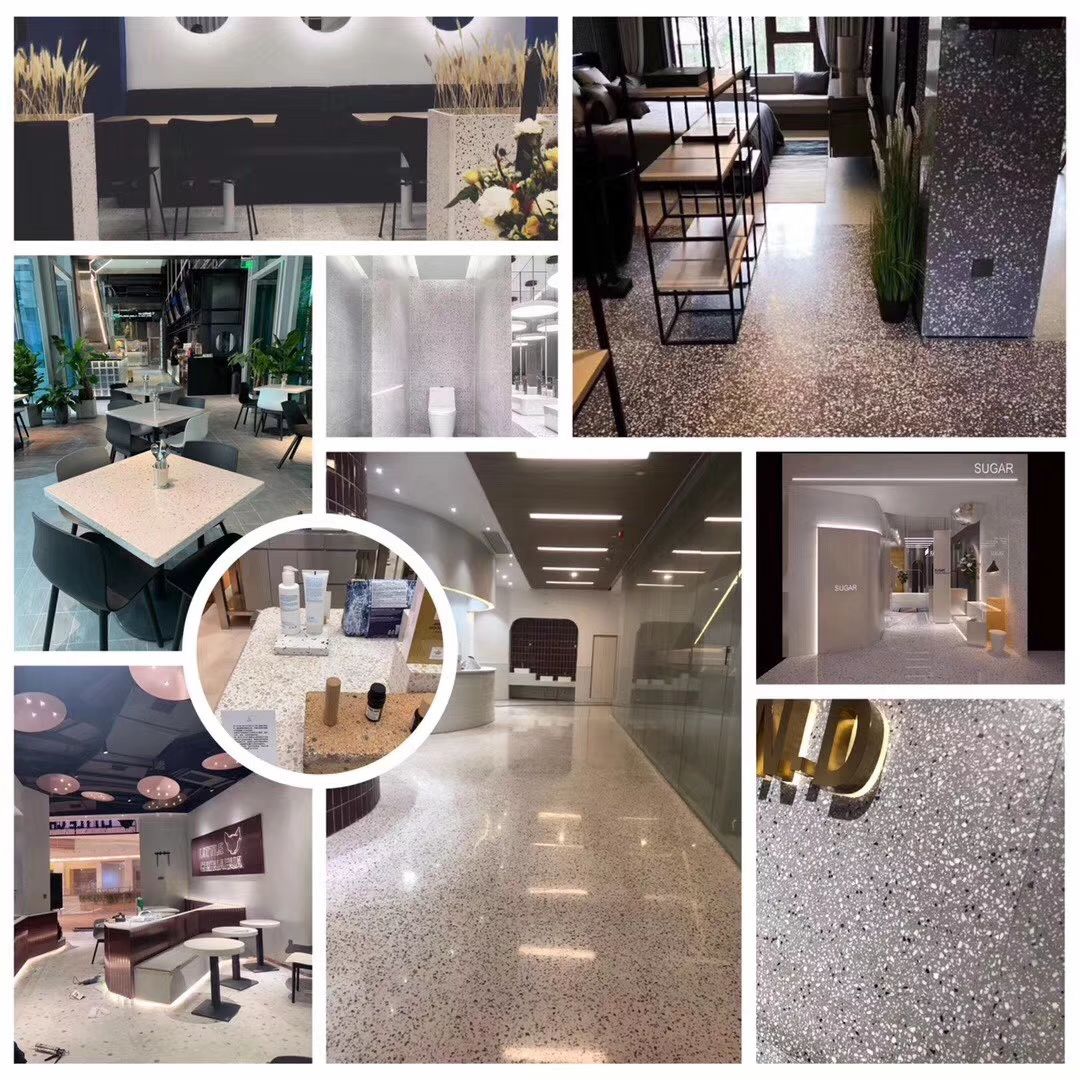

marble mosaic, carrara white, waterjet mosaic 3d fishbone, luxury , hexagon, herringbone, terrazzo tiles, cement flooring, terrazzo slabs, table top, cement terrazzo, countertop

Color:Black

marble mosaic, carrara white, waterjet mosaic 3d fishbone, luxury , hexagon, herringbone, terrazzo tiles, cement flooring, terrazzo slabs, table top, cement terrazzo, countertop

HOW TO MAKE TERRAZZO TILES AND SLABS

1. Various stone chips, grains, sands, colors seem disorganized in a terrazzo tile, truth is it's beautiful because its balance to all substances. Our lab is just like a magic place where tech workers scientifically matched all kinds raw materials, making finish products less porous and high strength, meanwhile considering the design of our clients.

2. Our lab will closely monitoring whole producing process and make final judge of quality of finished products

Workshop accept the scientific ratio of terrazzo pattern design from our lab. According to the quantity of required, workers will stir all kinds of ratio materials well, then the well stirred materials will transfer to 650 tons pressing machine where to press the mixture into die boxes (as 600*600mm tiles for example, a die box’s size will be 603*603mm). During the pressing process, vacuum machine will draw air from the mixture, to make the pressed tiles/pavers more strong and less porous.

The pressed raw block will be sent to steaming room, stay there for 24 hours, this process is known as natural curing, after 24 hours the major material concrete will solidify with other raw materials. Our factory located at north of China, where the temperature will fall to under 10℃, at that time, we will use heated steam to keep the steaming room’s temperature around 20℃.

Natural cured terrazzo raw tiles/pavers will then stored on steel shelves and put into pools, where water should covered all tiles/pavers, and stay under water for over 15 days(during winter time will be around 20 days because the low temperature). During this process, the alkali in the concrete will separate out into water, so as to make the tiles/pavers much more strong and avoid the whiskering phenomenon after the ensued paving. The water in the pool should be replaced regularly after it is alkali saturated, while my factory has installed a sewage treatment system, used water will be treated and recycling use.

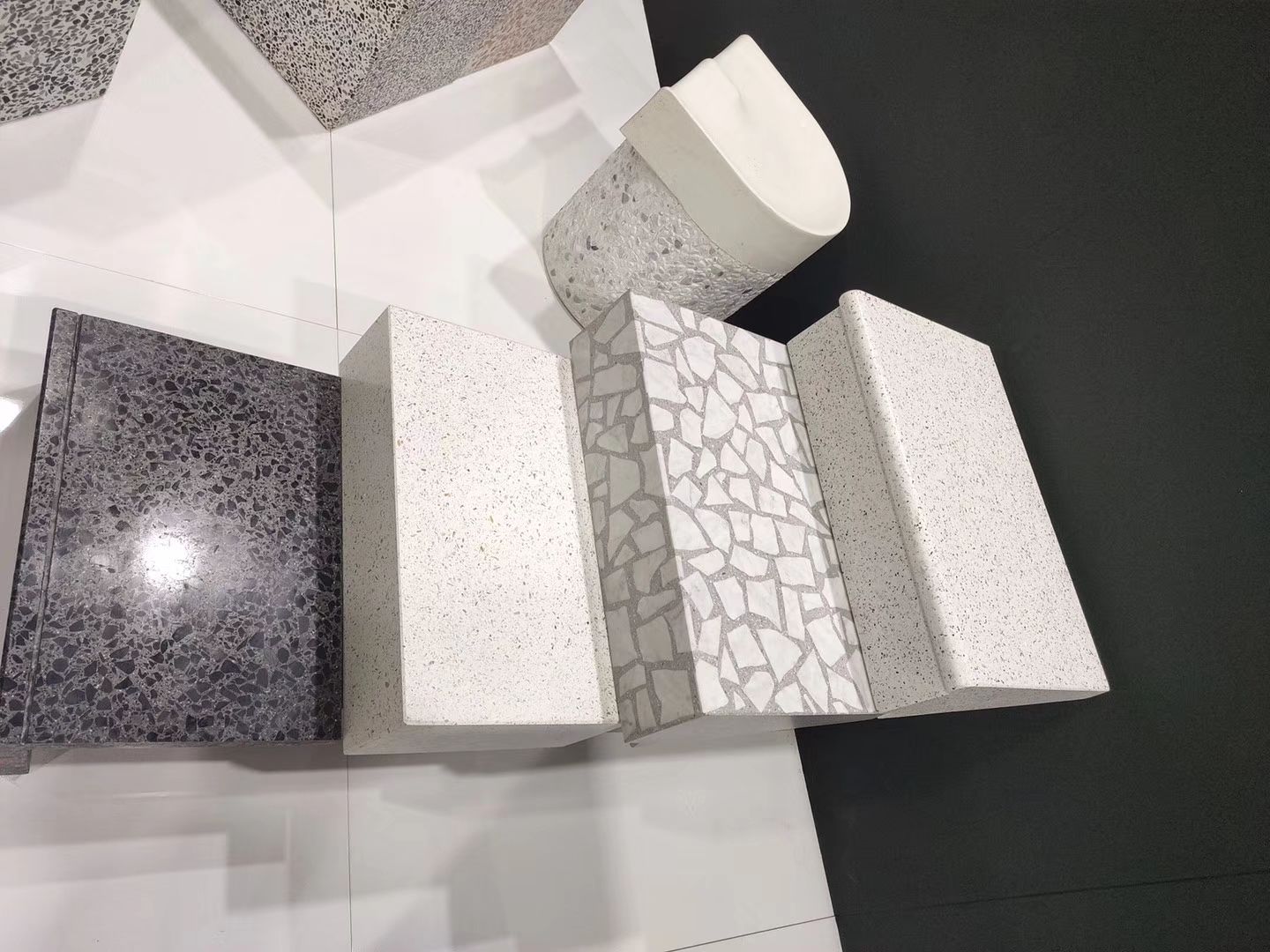

Since this step, the raw terrazzo tiles/pavers are ready to go to mechanical process. In which, first, the cutting machine will cut backside to the thickness needed, called thickness checking, then go to surface dealing process, the surface of terrazzo can be treated to polished , honed, sandblasted, brushed. At last, cut the side to need sizes(also can be champed to certain degree). a terrazzo tile/paver is done.

Package. We only use plywood case for export packing which don’t need fumigation. Tiles/pavers put upright into cases, there are foam boards between tiles, and tiles to case walls, to prevent breakage during transit. The outer of packed cases should be fasten by steel tapes and wrapped with plastic wrap, to avoid bad weather may happen during transit.

| Name | Terrazzo floor tiles,Inorganic Stone |

| Certificate | SGS |

| Grade | AAA |

| Water absorption | 0.29-1.1% |

| Flexural Strength | 9.7Mpa |

| Compressive Strength | 56.7-89.8Mpa |

| Finishing | Polished or Honed etc |

| Surface treatment | waterproof coating |

| Colour | Multi |

| Thickness | 20mm;25mm;30mm;custom is available |

| Tile Size | 400*400,600*600,800*800.,Any cut-to-size is available |

| Edge | Beveled;Eased;Bullnose and any shape according client's requirement. |

| Material | It consists of chips of marble, quartz, granite, glass, or other suitable material, poured with a cementitious binder (for chemical binding), polymeric (for physical binding), or a combination of both. |

| Advantage | Hign Resistant to Scratch |