Usage: Granite, Marble, Limestone, Onyx, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features

AUTOMATIC STRAIGHT EDGE POLISHER

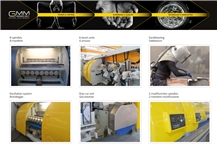

The Costa range of inline machines have been designed to work on all types of marble, granite, stone and agglomerates. These machines are versatile in order for them to work in small, medium or large size establishments in the building, design and monumental. Easy to use, these machines can be made to measure for all types off needs, both in the small and large industry.

FEATURES

BODY

Made in electro-welded structure, machined with cnc machinery. Thermal treatment to unstress materials due to welding. Surface for the belt is rectified and lined with a stainless steel plate, which can be replaced. Sandblasting and special treatment with zinc base and double component paints.

BELT

Three-layer, 30 cm wide belt has a grooved guide on the base to guarantee the maximum adherence of the belt to the line to be worked. Belt gliding surface is ground and covered with a special interchangeable wear-resistant steel plate.

SPINDLES

Same on all units. Cover for safety on all moving parts and a double labyrinth seal for better water and humidity resistance.

BEVELS

They make the double bevel on the straight edge. They are mounted at 45°. The two fi rst (up and down) have the possibility to use diamond tools and to reach a fi x position driven by the computerized system to obtain the perfect required bevel. Their entry and exit on the material is programmable regardless of the work on the straight edge.

CALIBRATORS, DRIP CUT, MULTI-FUNCTIONAL UNITS

Can be placed at the entry and exit of the machine. With various configurations, they allow to work with the axis in vertical position, inclined and horizontal. On these units we can install levigating heads, profiling tools, bush hammering unit, discs for cutting. In order to work properly we have motors with double speed.

BAR WITH MICRO OSCILLATING "BRANDEGGIO"

Allows to polish the edge using universal tools. The spindles all run with separate motors and are placed in a strong aluminium casting bar. A computerized system allows to program the micro-oscillating on the straight edges with large thickness.

TOUCH SCREEN

Electronics of the latest generation which allow simple and intuitive automatic programming the intervention of each units, also partial. Setting out of the thickness of the work piece there's the automatic positioning of: pressing bar and calibrator. The opening of the water and the start up of all electric motors is driven in automatic by the material arrival. This allow an important energy saving. It is possible to carry out analysis and statistics regarding the times and quantities produced, as well as processing quotes. Also it is possible to memorize all the parameters used to produce a certain piece and recall this data when necessary.

ELECTRICAL BOX

Is positioned on the machine.

PROTECTIONS

The covers are all in heavy duty fiberglass on the front side of the machines and in stainless steel on all single units. All the spindles have pressure gauge and separate pressure regulation.

Particular attention has been paid to the configuration of the machine in order for it to be easy for normal maintenance work and change of tooling.

OPTIONAL

Bar code reader.

Calibratore pneumatico ribaltabile (0°-90°) 1500/3000 rpm, 4,3/5,7 hp:

- Frontal cut;

- Upper calibration;

- Upper honing;

- Rough shaping;

- Lower calibration;

- Frontal calibration;

- Upper water drip cut (through cut);

- Lower drip cut (through cut);

- Inclined cut.

Multifunction, 1500/3000 rpm, 4,3/5,7 hp:

- upper through drip cut;

- upper honing;

- inclined cut;

- antisliping bush hammering (programmable).

Through cut spindles at 600 mm, 3000 Rpm, 4,5 hp:

- upper programmable cut (max 600 mm from the edge).

Italy

Italy