white fused alumina, brown fused alumina, black silicon carbide, green silicon carbide, calcined bauxite, Tabular alumina

$980-980

white fused alumina, brown fused alumina, black silicon carbide, green silicon carbide, calcined bauxite, Tabular alumina

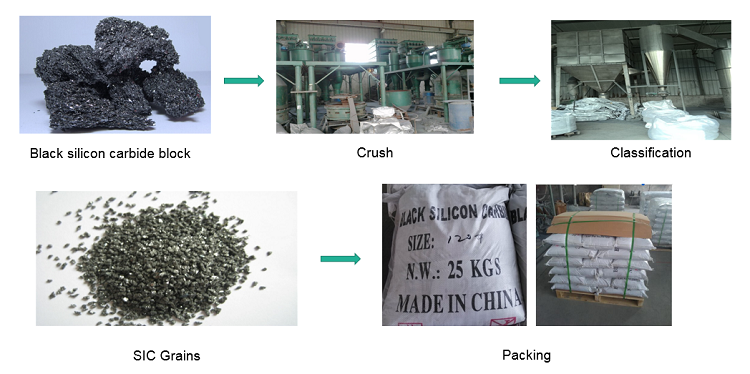

Product description: Black silicon carbide for grinding wheel

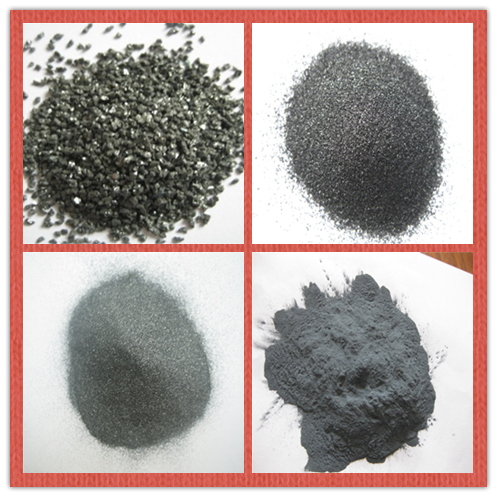

Black silicon carbide is made of quartz sand, petroleum coke (or coal coke), wood chips and other raw materials in the resistance furnace by high temperature smelting, resistance furnace by high temperature smelting, black opaque body, hexagonal crystal, Moh’s hardness of 9.15. Black Silicon Carbide contains some free silicon (Si) and carbon (C) and is not as pure as green SiC. It is ideal for a wide variety of applications including vitrified and resinoid grinding wheels, friction, blasting, compounds, lapping, polishing, non-slip, wiresawing silicon & quartz, and many more.

Chemical properties: Black silicon carbide for grinding wheel

Used for abrasives, lapping, polishing | ||||

Properties Type | FEPA | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000 | ||

JIS | 240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000# 6000# 8000# | |||

Guarantee Value | Typical Value | |||

Chemical composition | SIC | 97.0 min | 97.5 | |

F.C | 0.3max | 0.2 | ||

Fe2O3 | 0.2 max | 0.15 | ||

H2O | 1.0max | 0.3 | ||

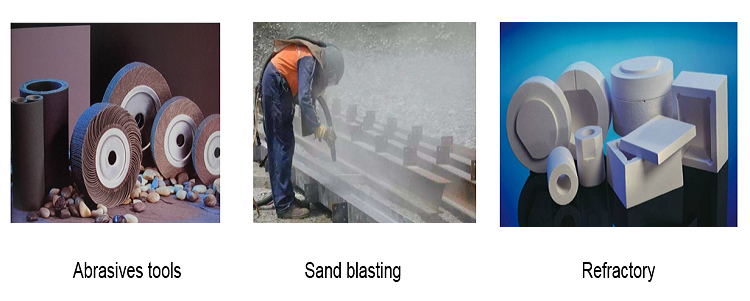

Application: Black silicon carbide for grinding wheel

1.Abrasive materials

It is mainly used for grinding wheel, sandpaper, asphalt, grinding head, grinding paste and surface grinding and polishing of mono crystalline silicon, poly crystalline silicon and various devices in photo voltaic products.

2.Advanced Refractories

It can be used as metallurgical deoxidizer and high temperature resistant material to make high temperature kiln components and supporting parts.

3.Functional ceramics

Improving the quality of kiln products and shortening the period and is the ideal indirect materials for ceramic glaze baking and sintering, used for high temperature non-oxide ceramics and reactive sintering ceramics.

4.Nonferrous metal

Used for Iron and steel industry, metallurgical mineral processing industry.

If you have another question, pls feel free to contact me.