TOWER Vertical Edge Polishing Machine For Straight Edges

Stone Factory MachinesStone Finishing, Profiling MachinesEdge Profiling, Polishing Machine

GMM

Italy

Italy

Usage: Granite, Marble, Limestone, Onyx, Artificial Stone, Basalt, Quartzite, Sandstone, Travertine

Machinery Function Features

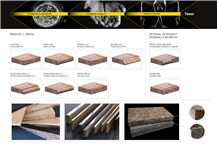

Automatic multi-spindle belt polishing machines for the execution of round and flat edges on any type of material (marble, granite, composite and cement agglomerates). The range of GMM edge polishing machines includes horizontal and vertical machines able to process thicknesses from 4.5 up to 100 mm. The shaping of the profiles is performed with universal abrasive wheels (avoiding the use of expensive shaped wheels). The machine management is entrusted to an electronic control of the latest generation (operating in 4.0 ready logic) supported by a SW entirely developed by GMM to ensure an easy and intuitive use to the operators. The oscillating bar (which supports the hydraulic motors with the abrasives for polishing) of the Toro bull-nosing machine, is driven by 2 brushless motors in order to guarantee high precision and best quality of the profile. All surfaces are treated with sandblasting, cold galvanizing primer and two-component painting. All the carters are in fiberglass or stainless steel.

FEATURES

MACHINE BED

Strong electroweld, fully worked with numeric control machines. Sanding followed by a cold-galvanized treatment and two successive coats of dual component epoxy paint.

BELT

Three-layer, 30 cm wide belt has a grooved guide on the base to guarantee the maximum adherence of the belt to the line to be worked. Belt gliding surface is ground and covered with a special interchangeable wear-resistant steel plate.

SPINDLES

Standard: identical on all work units. Fitted with a bellows for slide protection and having a double labyrinth seal to protect from water, moisture and dust. To further guarantee the seal, there is a slight internal pressure.

SPINDLE-HOLDER BAR

Polishes the edges, using universal tools. The spindles, each one controlled by its own electric motor (protection IP65), are housed in a sturdy sealed bar which empties the water directly into the tank. The computerized system allows programming by inverter a microoscillation (“swing”) above all on straight, thick fl at edges to increase the work speed and improve the degree of polishing. The abrasive discs used are 130 or 150 mm in diameter.

BEVELLERS

Mounted in opposition at 45° angles, they make a double bevel on the straight edge using a 130 mm diameter abrasive disc. The first pair of bevels has a mechanical stop for the use of diamond tools.

TOUCH SCREEN

Allow to manage all the functions of the machine. In particular it is possible to program the entrance and the exit of each unit to ensure quality and precision on all specific working. Are allowed the partial workings (Optional).

ROLLERS

The machine is equipped with two, 1-meter rollers, one at the entrance and one at the exit, respectively. Each roller is equipped with side rails to prevent the piece from tipping.

TANKS

The machine is equipped with several stainless steel water collection tanks to maintain proper functioning and the duration of individual components.

GUARDS

The external casings are in sturdy fibreglass while the pressing bar and the single unit guards are in stainless steel.

OPTIONAL

Partial bevelling work.

Calibrating.

Technical Data

| Parameters |

Unit |

TOWER 72-74 |

TOWER 72G |

TOWER 74G |

| No. calibrating/shaping/cutting spindles |

nr |

1 (Optional) |

1 (Optional) |

1 (Optional) |

| Machine overall width |

mm |

1350 |

1350 |

1350 |

| Number of optional bevel spindles |

nr |

1-2 |

- |

- |

| Number of dressing/polishing spindles |

nr |

7 |

7 |

7 |

| Min. processing width |

mm |

45 |

45 |

45 |

| Approx. Weight |

Kg |

2550 |

2550 |

2900 |

| Grinding tool diameter |

mm |

130÷150 |

130÷150 |

130÷150 |

| Min. processing thickness |

mm |

8 |

8 |

8 |

| Number of Drip cut unit |

nr |

- |

1 |

1 |

| Machine overall length |

mm |

3400 |

3400 |

3800 |

| Dressing/polishing spindle power |

hp |

14 |

14 |

14 |

| Max. processing thickness |

mm |

60 |

60 |

60 |

| Automatic management end of abrasive |

yes/not |

optional |

optional |

optional |

| Machine overall height |

mm |

1600 |

1600 |

1600 |

| Number of Bevelling/chamfering spindles |

nr |

2 (45°) |

2 (45°) |

4 (45°) |

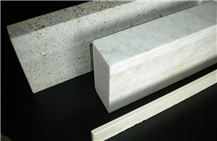

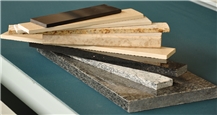

Processed Stone Photos

-

edge profiles

-

edge profiling

-

trims

After-Sale

-

Warranty: 12 Months

-

Install and Guarantee:Customer pay for installation, Remote guidance installation, Third-party team installation

-

Maintenance: Online software upgrade, Regular guidance & maintenance, Remote troubleshooting

Supplier Detail

Gmm S.p.A.

Italy

Main Product:

sawing bridge machines, polishers, lathe machine, block cutter, bridge saw machines, CNC Machine, Calibrating Machine, waterjet machine, wire saw

Simone Guazzoni

Tel:

+39 0 323 864381

Adr:

Via Nuova, 155 - 28883 Gravellona Toce (VB) Italy

Visit Store

Italy

Italy