Machinery Function Features

WORKING CENTRE FOR SHAPING, CONTOURING, SAWING AND TURNING MARBLE, GRANITE, SANDSTONE

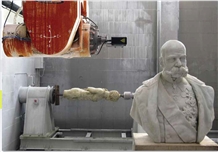

ShapeMill NCF 1600 and NCF 2000 are machine specially engineered for workshops producing pieces made from natural and composite stone, such as tanks, columns, bas-reliefs, capitals, banisters, sculptures, etc., and particularly suitable for restoration works.

SHAPEMILL NCF is a CNC milling centre designed for contouring, cutting and turning with five interpolated axes and a fixed work-table offering users the possibility of multiple and complex machining operations which would otherwise require several machines:

shaping of blocks or billets utilising a saw blade to obtain large size workpieces with complex shape

shaping and creating recesses utilising milling tools

contouring utilising shaped tools

cutting slabs and billets into workpieces utilising a saw blade

turning of columns with shaped profiles or machining of columns to create a twisted effect all along the surface.

SHAPEMILL NCF STANDS OUT FOR PERFORMANCE

- “rapid” displacements of up to 40 metres per minute;

- giant work-table sizing up to 4.000x3.500 mm

- powerful high-frequency spindle of 39.6 kW;

- max. diameter of the cutting saw blade: 1.000 mm;

- “C” axis rotation: ± 200°;

- “A” axis rotation: from 0° to +115°;

- “X” axis travel: 4.000 mm;

- “Y” axis travel: 2800/5.500 mm;

- “Z” axis travel: 1.600/2.000 mm;

- possibility of using various saw blades, shaped tools, drills, millers, etc.;

- automatic tool-store with 27 positions + (optional) 2 positions for the saw blade.

SHAPEMILL STANDS OUT FOR ITS STRUCTURAL FEATURES

- steel work-table secured to the ground, with aluminium top with recesses for mounting fixtures to secure the work piece in place.

- beam with “gantry” movement along the shoulders (“X” axis) on ground guides and roller sliding block assemblies; the drive assembly consists of a pinion-and-rack system with rack precision to hundredths, with 6 DIN 3961 Alpha quality grade, and precision reduction gears with Alpha backlash adjustment system; the motorization is by Siemens digital brushless-type motors.

- spindle carriage manufactured from iron casting and moving on roller sliding block assemblies ( “Y” axis); the drive assembly consists of a precision pinion-and-rack system powered by a digital brushless-type motor. The spindle steel cylinder (“Z” axis) is positioned vertically on the inside of the carriage and is moved by a ball bearing screw / preloaded lead nuts / digital brushless-type motor system. Provided with a pneumatic balancing system.

- birotary head for interpolated 5-axis machining. The head has a symmetrical structure and consists of two main structural elements, the first (“C” axis) is fitted with a Schleifring slip ring system for ± 200° rotation around its own vertical axis and the second element (“A” axis) rotating from 0° to +115° and housing the high-frequency spindle. Rotation transmission are provided by brushless-type motors.

- 6-pole 39.6 kW high-frequency spindle, cooled by a closed circuit electric-cooling system, which has a rotational speed of up to 7.000 rpm and a steep torque curve so as to supply the maximum power even when rotating slowly (e.g. with a 1.000mm ø saw blade at 1.000 rpm, the maximum power is supplied).

The high-frequency spindle is fitted with a HSK-A100 (HSK-B100 NCF2000) conical coupling for the milling tools and saw blade and provided with an internal and external tool cooling system.

breton-shapemill

- Carousel tool magazine with 27 cells.

- store for saw blade with a max. diameter of 600 mm, secured to the side shoulders, for 2 positions as a maximum (optional accessory).

- lathe for producing columns and twisted effect details with workable sizes: ø 1.080/1.600 x 3.200 mm (optional accessory)

- frontal protection barrier consisting of a series of sliding doors with manual opening; doors are made from structure and are provided with wide inspection ports. The rear part of the milling centre is closed by a set of steel plate panels.

- Siemens Sinumerik 840D SL: the latest digitally-controlled computer numerical control system, with PC architecture and a PC unit utilising Windows as operating system, with Windows user-friendly interface and fully-developed software for work program management.

SHAPEMILL Teleservice. An Internet connection is required in order to ensure an effective technical support in case of need.

- control console mounted on a mobile pendant structure and equipped with a 15-inch touch-screen colour monitor, a joystick to easily move the motorized working axes movement and a USB port for data transfer.

- portable mini console, wired to the main control console, to duplicate the major controls (axes management + hand-wheel, emergency shut-down, etc.); this portable mini console allows the operator to be close to the piece to be machined thus controlling directly some delicate machining operations.

- electrics and utilities are housed in two cabinets with IP54 grade of protection and cooled by an air conditioning unit specially designed for a maximum external temperature of +45°C.

- superior quality components:

- racks with precision up to hundredths and 6 DIN 3961 Alpha quality grade

- precision reduction gears with Alpha backlash adjustment system

- Siemens digital brushless-type motors

- Schleifring rotating slip ring

- Siemens CNC unit

Italy

Italy