fused alumina, silicon carbide , Ceramic Sand, tabular alumina, boron carbide, Foundry Sand

fused alumina, silicon carbide , Ceramic Sand, tabular alumina, boron carbide, Foundry Sand

Grit blasting glass beads 60# 70# 80#

Grit blasting glass beads 60# 70# 80#

Glass beads blasting media for alloy polishing from HAIXU Abrasive was made from glass sand which crushed by glass blocks and plate glass, fused by high temperature in the electric furnace.

Glass beads blasting media for alloy polishing from HAIXU Abrasive can be safe compared to other blast media. In particular, glass bead blast media can be a good alternative to silica sand depending on your application, which while silica sand is still legal it is becoming more regulated and is recognized as a source of a variety of health problems including silicosis.

Technical datasheet:

| TYPICAL CHEMICAL ANALYSIS | TYPICAL PHYSICAL PROPERTIES | ||

| SiO2 | 71.0% | Hardness: | Mohs:6-7 HRC:46 |

| NaO2 | 14.0% | Specific Gravity: | 2.5 g/cm3 |

| Fe2O3 | 0.1% | Bulk density(LPD): | 1.6 g/cm3 |

| Al2O3 | 2.0% | Refractive Index(RI) | ≥1.5 |

| MgO | 4.0% | Round rate | ≥80.0% |

| CaO | 7.0% | Magnetic content | Black |

| Magnetic content | ≤0.1% | Particle appearance: | colorless, glass transparent without impurities, Round and smooth |

| Others | 0.016 | ||

Glass beads Specification for sandblasting:

| GB NO. | Mesh(U.S. standard) | BEAD SIZE RANGE (Dia. um) | BEAD SIZE RANGE (Dia. Inch) |

| GB NO.3 | 20-30 | 850-600 | 0.0331-0.0234 |

| GB NO.4 | 30-40 | 600-425 | 0.0234-0.0165 |

| GB NO.5 | 40-50 | 425-300 | 0.0165-0.0117 |

| GB NO.6 | 50-70 | 300-212 | 0.0177-0.0083 |

| GB NO.7 | 60-80 | 250-180 | 0.0098-0.0070 |

| GB NO.8 | 70-100 | 212-150 | 0.0083-0.0059 |

| GB NO.9 | 80-120 | 180-125 | 0.0070-0.0049 |

| GB NO.10 | 100-170 | 150-90 | 0.0059-0.0035 |

| GB NO.11 | 120-200 | 125-75 | 0.0049-0.0029 |

| GB NO.12 | 140-230 | 106-63 | 0.0041-0.0025 |

| GB NO.13 | 170-325 | 90-45 | 0.0035-0.0017 |

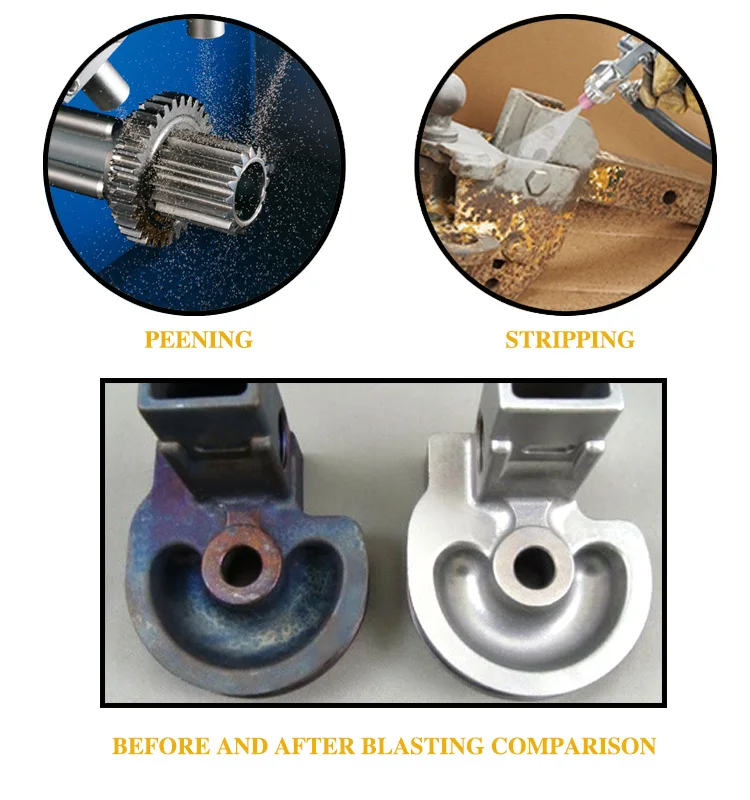

Glass beads blasting media for alloy polishing from HAIXU Abrasive is the common uses for glass bead blasting. Glass bead blasting is well suited for use in sandblasting cabinets where blast media will be recovered. It is effective at cleaning a surface without leaving much of a blast profile. This makes it ideal for cleaning paint or coatings off a part as well as the removal of rust. If a profile is needed though blast media like steel grit or aluminum oxide can be required as glass bead typically doesn’t profile when blasting.

We are a manufacturer, which can control the cost easier than trade companies also can give you answer more quickly.

As a manufacturer, we know much in technique and can give you more support in technique problem

Professional and experienced service team, specialized in abrasive production, more than 10 years.

Our products are complete in specifications with various sizes

We enjoy a good reputation in the customers in domestic and overseas markets.

Large production capacity, short lead time of products.

24*7 online service.

Grit blasting glass beads Grit blasting glass beads Grit blasting glass beads Grit blasting glass beads Grit blasting glass beads Grit blasting glass beads Grit blasting glass beads Grit blasting glass beads Grit blasting glass beads Grit blasting glass beads Grit blasting glass beads Grit blasting glass beads Grit blasting glass beads Grit blasting glass beads