fused alumina, silicon carbide , Ceramic Sand, tabular alumina, boron carbide, Foundry Sand

fused alumina, silicon carbide , Ceramic Sand, tabular alumina, boron carbide, Foundry Sand

Sandblasting SiC green silicon carbide grit

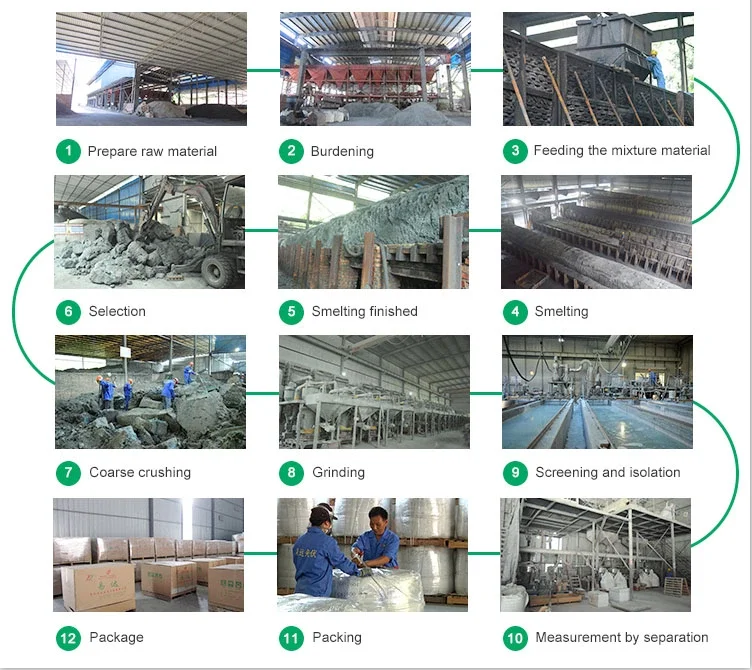

Green Silicon Carbide is produced at high temperature in an electric resistance type furnace with quarts sand and petroleum coke. It is a synthetic brittle carborundum with high thermal conductivity and high strength which get no decrease in 1000℃( 7.5 times stronger than Alumina)

Green silicon carbide is characterized by extreme hardness (Mohs 9.4/2600 Knoop) which only ranks after CBN and B4C.

Green silicon carbide abrasive from HAIXU Abrasive offers superior properties such as:

| TYPICAL PHYSICAL PROPERTIES | |

| Hardness: | Mohs:≥9.4 |

| Melting Point: | Sublimes at 2600 ℃ |

| Maximum service temperature: | 1900℃ |

| Specific Gravity: | 3.2g/cm3 |

| Bulk density(LPD): | 1.2-1.6 g/cm3 |

| Color: | Green |

| Particle shape: | Hexagonal |

| TYPICAL CHEMICAL ANALYSIS | |

| SiC | 99.05% |

| SiO2 | 0.20% |

| F,Si | 0.03% |

| Fe2O3 | 0.10% |

| F.C | 0.04% |

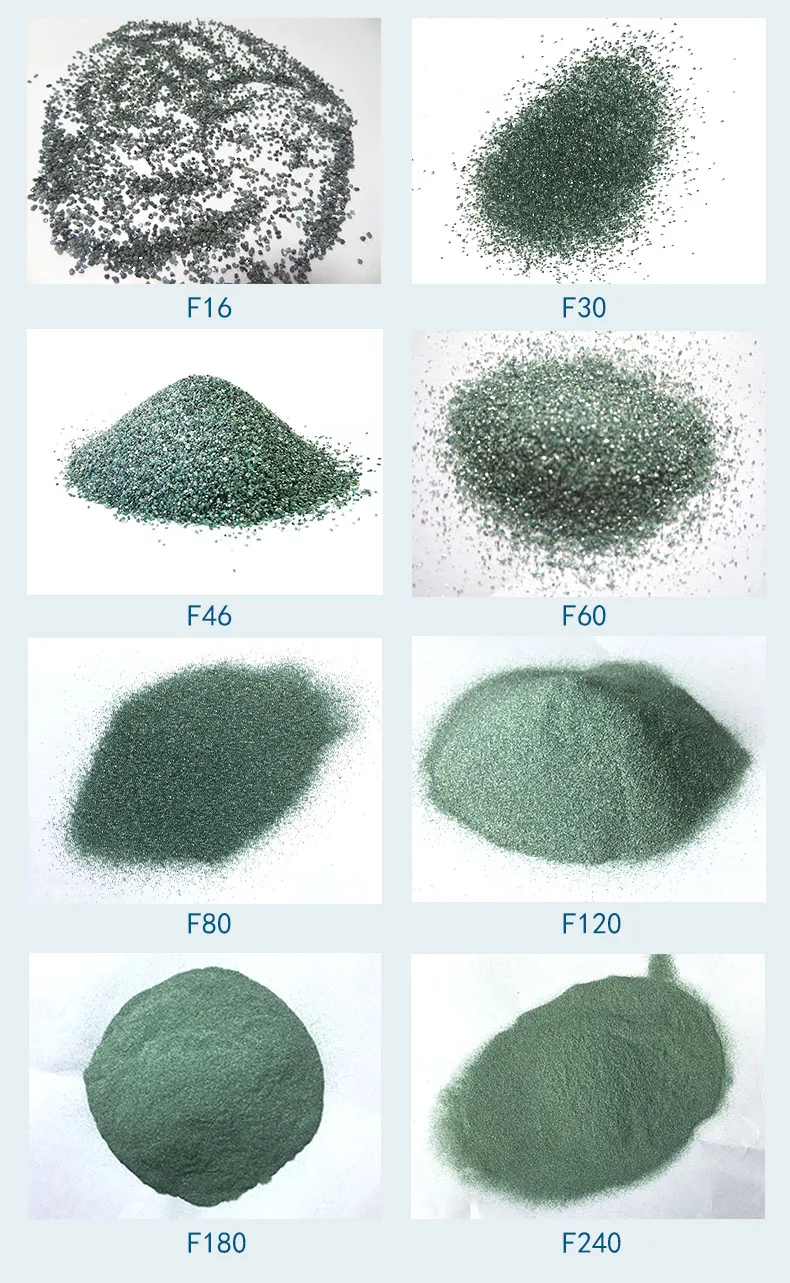

Available grit Sizes:

| F-macrogrits sizes bonded | |

| Grit designation | Mean diameter in um |

| F4 | 4890 |

| F5 | 4125 |

| F6 | 3460 |

| F7 | 2900 |

| F8 | 2460 |

| F10 | 2085 |

| F12 | 1765 |

| F14 | 1470 |

| F16 | 1230 |

| F20 | 1040 |

| F22 | 885 |

| F24 | 745 |

| F30 | 625 |

| F36 | 525 |

| F40 | 438 |

| F46 | 370 |

| F54 | 310 |

| F60 | 260 |

| F70 | 218 |

| F80 | 185 |

| F90 | 154 |

| F100 | 129 |

| F120 | 109 |

| F150 | 82 |

| F180 | 69 |

| F220 | 58 |

Blasting, surface Treatment for glass, ceramic, etc.

Ceramic products

Raw material of GC grinding wheel, sandpaper, abrasive cloth suitable for marble and granite.

Grinding hard alloy ,non-ferrous metal, plastic, etc.

Raw material of Whetstone, oilstone, grinding stone, abrasive stones and so on.

Ø We are a manufacturer, which can control the cost easier than trade company also can give you answer more quickly.

Ø As a manufacturer, we know much in technique and can give you more support in technique problem

Ø Professional and experienced service team, specialized in abrasive production ,more than 10 years.

Ø Our products are complete in specifications with various of sizes

Ø We enjoy a good reputation in the customers in domestic and overseas markets.

Ø Large production capacity, short lead time of products.

Ø 24*7 online service.