acrylic, polyurethane sealant, epoxy sealants, Stone adhesives, abrasives, waxes, Sealers and impregnators

acrylic, polyurethane sealant, epoxy sealants, Stone adhesives, abrasives, waxes, Sealers and impregnators

POLYCRYSTAL SEALANT/ADHESIVE, MONOCOMPONENT of HIGH PERFORMANCE (for assembly) in cartridge

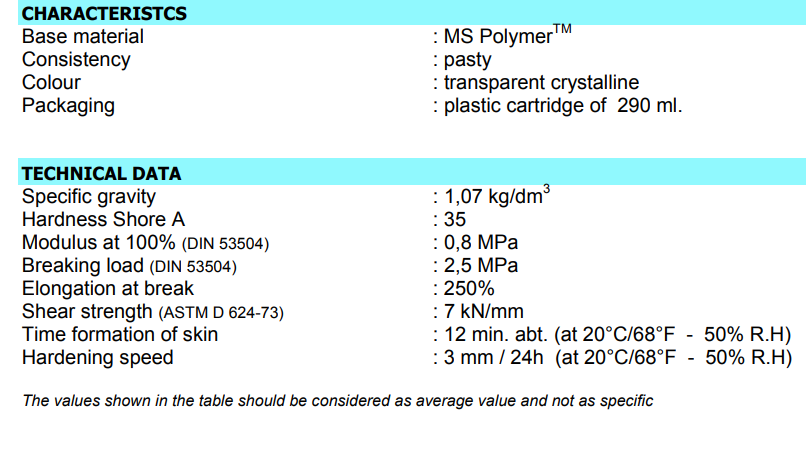

DESCRIPTION Monocomponent adhesive sealant, hardening by atmospheric humidity, based on MS PolymerTM . Transparent and crystalline, also in thickness, of high elasticity and cohesion, adheres to wide kind of surfaces. By POLYCRYSTAL is possible to make elastic sealing of high performance. The high cohesion capacity allows its use also for very little visible bonding with high filling capacity. • Free from solvents, isocyanates, silicon • Practiclly without shinkage • Flexible at low (-40°C/-40°F) and high (+100°C/+212°F) temperatures • Neutral reaction • Odourless • Very short grip time • Excellent adhesion to a wide kind of substrates • High cohesive power • Very good resistance to UV radiation • Paintable

FIELD OF USE • Indoor sealing of joints between metal, painted metals, glass, glazed surfaces, plastics (except PE. PP, PTFE), • Very little visible elastic bonding of glass, plastics (except PE, PP, PTFE), ceramics, metal, painted metals, woods in the furniture and decorative industry, building and construction industry, means of transport, wood • Not hazardous adhesive sealant of general use for industry and “do-it-yourself”

APPLICATION Adhesion and Preparation of the surfaces, Application, Joints size POLYCRYSTAL ha san excellent adhesion without the use of primer on degreased surfaces of steel, galvanized steel, anodized aluminium, aluminium, painted surfaces, on cement, wood, glass and glazed surfaces, ceramic, natural stone, polyester, UPVC. For special operating conditions, such as the presence of moisture or on porous surfaces, you can improve the adhesion with the application of appropriate primer Preparation of the surface Surfaces must be clean, free from greasy substances, dust and any loose particles or friable parts. Application Apply the sealant with continuity exerting an adequate pressure between the support and the material to be bonded and / or against the walls of the joint. Within 10-15 minutes from the application, the sealant can be finished or smoothed Joints sixzes A joint properly realized ensures the maximum capacity of absorption of the movements of the sealant, and therefore a long life and efficiency of the sealing. The joints subject to movement must have a size and a shape compatible with the elongation of the sealant capacity; rectangular sections with a depth less than the width and the adhesion only on the side walls, minimize stresses on the adhesion and tearing. For a correct dimensioning of the section and to prevent the sealant adheres to the third wall, we recommend inserting on the bottom of the joint a non-stick profile of polyethylene foam

STORAGE STABILITY Stored in a dry place at temperatures between +5°C/41°F and +25°C/77°F, in the original packaging (290 ml cartridge.), the product will remain stable for 12 months. Protect from frost